The New Trend 2017: 3D Scanning for Jewellery

The New Trend: 3D Scanning for Jewellery

Reading Time:

1 min {{readingTime}} mins

Imagine being able to copy anything in perfect detail at the touch of a button. Only ten years ago this would just have been merely a pipe dream. Now the dream has become reality. David Valle of Gala Creations takes us through what you need to know about 3D scanning and its every day uses for the jewellery industry.

What is 3D scanning?

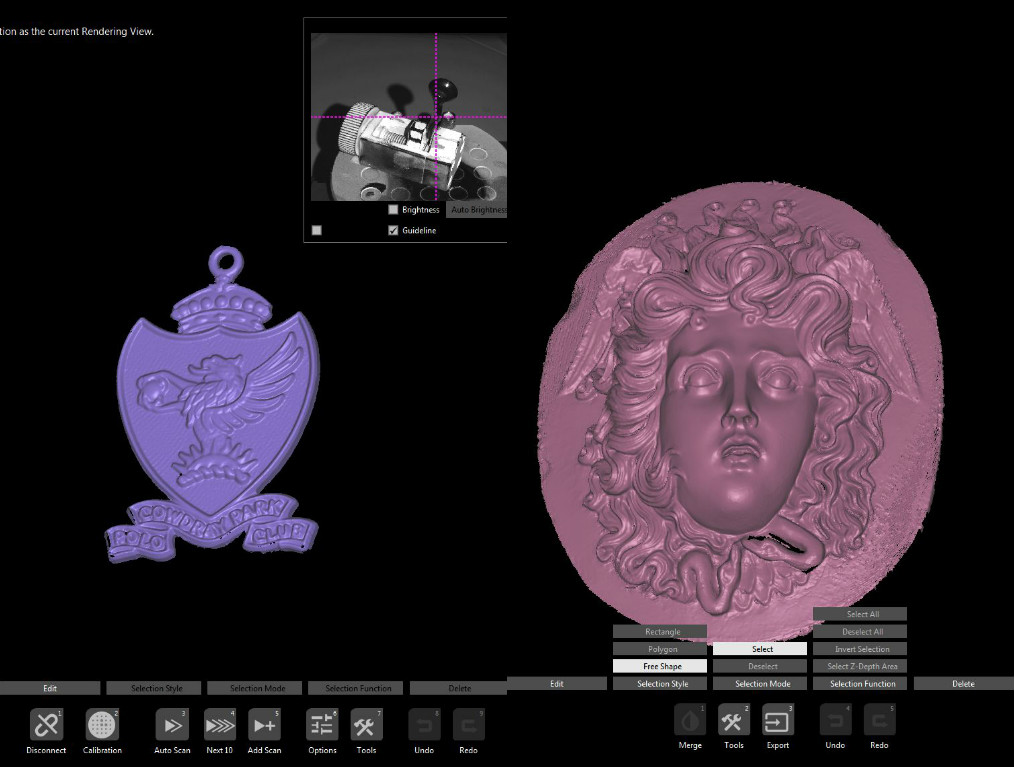

3D scanning is the technology used to digitalize any small object, including any type of jewellery, wax and gemstone.

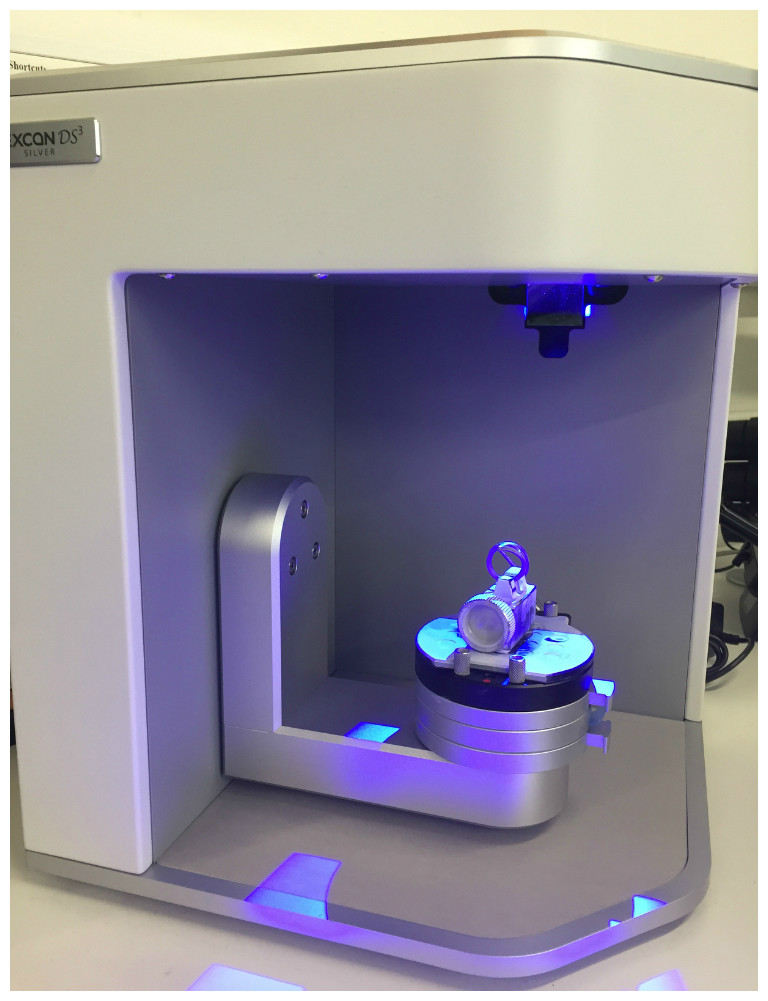

3D scanners work by shining different patterns and intensities of light onto an object to be scanned. Then, a built-in camera uses specialist software to analyse the hundreds or thousands of measurements generated by the bright and shaded areas projected onto the object in order to create a 3D file.

Different types of scanners

Scanners can be hand-held or fixed, with fixed generally considered the superior mode for jewellery in order to capture a high level of detail on a small object without the requirement for a supremely steady hand.

Different scanners work in different ways with older technologies functioning through physical touch or via white structured light and with the most up-to-date technologies using lasers or blue structured light.

Uses for scanners in jewellery

Jewellery Replication

By scanning a piece of jewellery it can be re-made as a precise copy of the original in terms of both metal and stones; something which is both difficult and time-consuming for a CAD Designer. There are many reasons why this could be required including reproducing a handmade ring, changing the size of items such as eternity rings and pendants, remaking broken jewellery and copying an existing model in wax or metal to make a range of jewellery offering different thicknesses, stone sizes or other variations.

Everyday Objects

Now anything can easily become a piece of jewellery merely by scanning it, be it a leaf, child's toy or a piece of fruit.

Opening up a whole range of creative possibilities, designers can now draw inspiration from the most unlikely source in the world surrounding them.

Fitted Wedding Bands

It is increasingly popular for brides to opt for fitted wedding bands around their engagement ring. Using a 3D scanner provides the perfect outline of the engagement ring, allowing a 100% accurate fit on the wedding band designed using 3d software such as Matrix or Rhinojewel.

Gemstones/Diamonds:

By scanning stones, a CAD Designer can create 100% accurate settings within their model; the ideal option for fancy cut stones.

Insurance

3D scanning allows businesses to keep 3D files of all their stock for insurance or valuation purposes. Personal customers can keep a precise record of their precious jewellery pieces so that if the worst should happen, the items can be easily replicated.

About the Contributor

David Valle is Director of Gala Creations Ltd, a high end jewellery manufacturing firm specialising in CAD, prototyping and 3D scanning. He has almost 30 years of experience in the jewellery industry, starting his career as an apprentice in his family’s workshop in Bilbao, Spain before moving to the UK 20 years ago to specialise as a wax model-maker.

David maintains a keen interest in new technologies and he has spent the past 10 years perfecting his skills in the CAD arena at the same time as accumulating 3 different prototyping machines and a 3D scanner.

Renowned as the CAD specialist who can achieve ‘the impossible’, he counts most of the premier names in jewellery in the UK amongst his clients.

Gala Creations, Unit 1.02 The Goldsmiths Centre 42 Britton Street London. EC1M 5AD

Author:

Published: