Extraction measures in the workplace

Open letter to industry - fume and dust extraction measures are often inadequate

Reading Time:

1 min {{readingTime}} mins

Paul Riddick, Technical Sales Director at VODEX Ltd, has written an open letter to the jewellery industry to highlight the legal requirements and responsibilities of providing and working in a clean and safe environment.

To whom it may concern,

Jewellery-making is a profession rife with workplace dangers that staff and artisans need to be protected against. Unfortunately, fume and dust extraction measures are often inadequate, posing a risk to health.

Legal Requirements and Responsibilities

In the UK, jewellery business employers must comply with The Health and Safety at Work Act 1974, and the COSHH Regulations 2002 (as amended) which mandate risk assessments for hazardous substances.

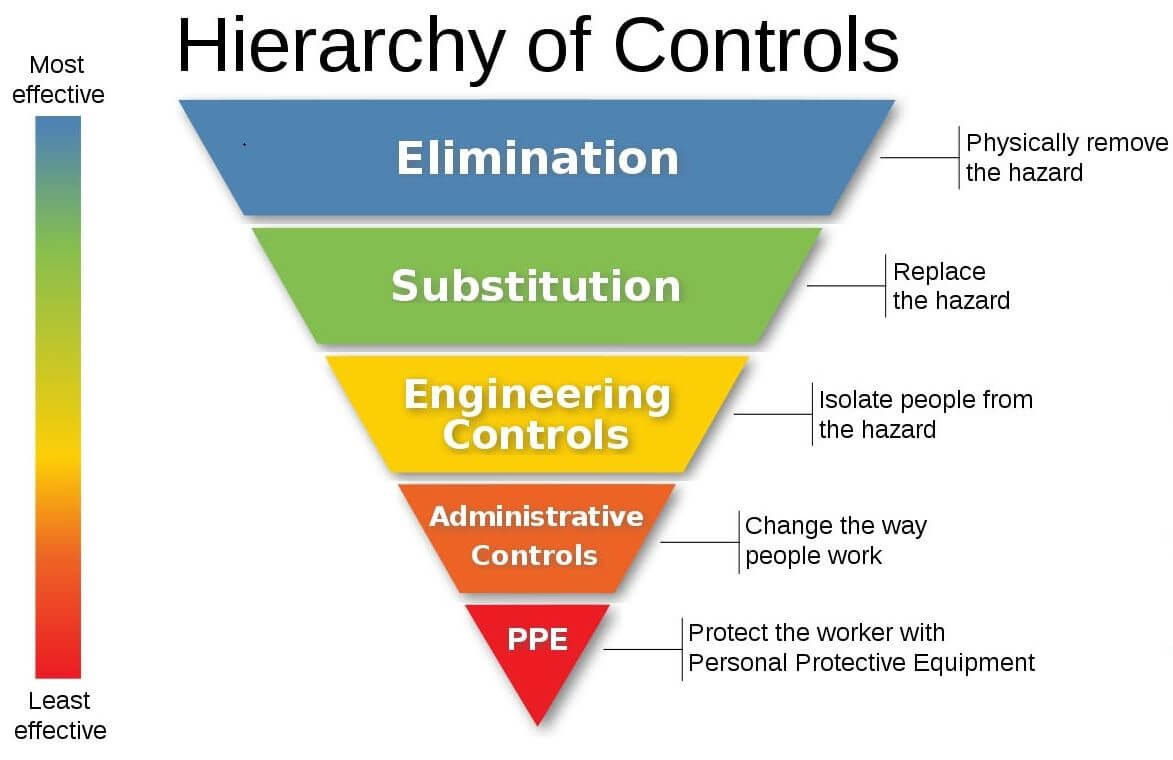

Note: There is a legal requirement under COSHH (Control of Substances Hazardous to Health) Regulations to follow the hierarchy of controls as laid out below:

If total removal of the substance/process or ‘substitution’ is not possible, then ‘engineering controls’ is the next level of defence – this means the installation of Local Exhaust Ventilation in the first instance.

Understanding the Hazards

But, before we delve into the solutions, we first have to understand the occupational hazards plaguing jewellery workers before we can properly protect against them. These include:

- Casting fumes

- Fumes from heating and melting metals

- Cutting, Filing and Grinding dust

- Soldering Fumes

- Polishing/Linishing Dusts

- Plating Fumes

- Pickling Fumes

Along with the potentially dangerous dusts given off by energy-intensive processes like grinding and polishing, other hazards include:

- Acid and Enamelling fumes

- Solvents and Ketones

- Aqua Regia

- Cadmium

- Cyanides

- Resins

- Fluxes/Borax

- Mica

- Xylene

These substances, if inhaled, can cause severe health issues, including headaches, dizziness, lung damage, skin and eye irritation, and are sometimes carcinogenic.

The Importance of General Ventilation

I am sure there are many jewellers and goldsmiths out there who are not ventilation or filtration specialists, and many are not aware of the health hazards they are being exposed to on a daily basis.

'General ventilation' in any small or large workshop is always good practice. It prevents stale air and creates a pleasant working environment; however, it is always seen as secondary to ‘at source’ extraction, where the substance or fumes can be extracted (and filtered) BEFORE they become airborne.

By ‘general ventilation’, we mean, in the most basic form, opening a window or using a passive air system with unfiltered extractor fans as a low-cost 'quick' fresh air solution.

However, in colder months, one may need to consider the potential heat loss from the room or workshop. In an average-size room of 4m x 4m x 2.5m (40m3), with 10-12 air changes per hour, one would need extraction flow rates of well over 450m3/hr. That's 450 cubic metres of warm air loss every hour!

So, over an eight-hour day, this could easily exceed 4,500m3 of warm air/heat loss. This heat needs replacing at considerable additional cost. Some workshops may have the advantage of a heat exchanger unit fitted, which will reduce this to some extent, but most don't have his luxury.

Before we go too deep into this subject, you need to understand ‘dust particles’ and how they can affect the body. You must always fully protect your ‘breathing zone’ (especially if you suffer from asthma, etc.) from very harmful airborne dust and chemical vapours/smells.

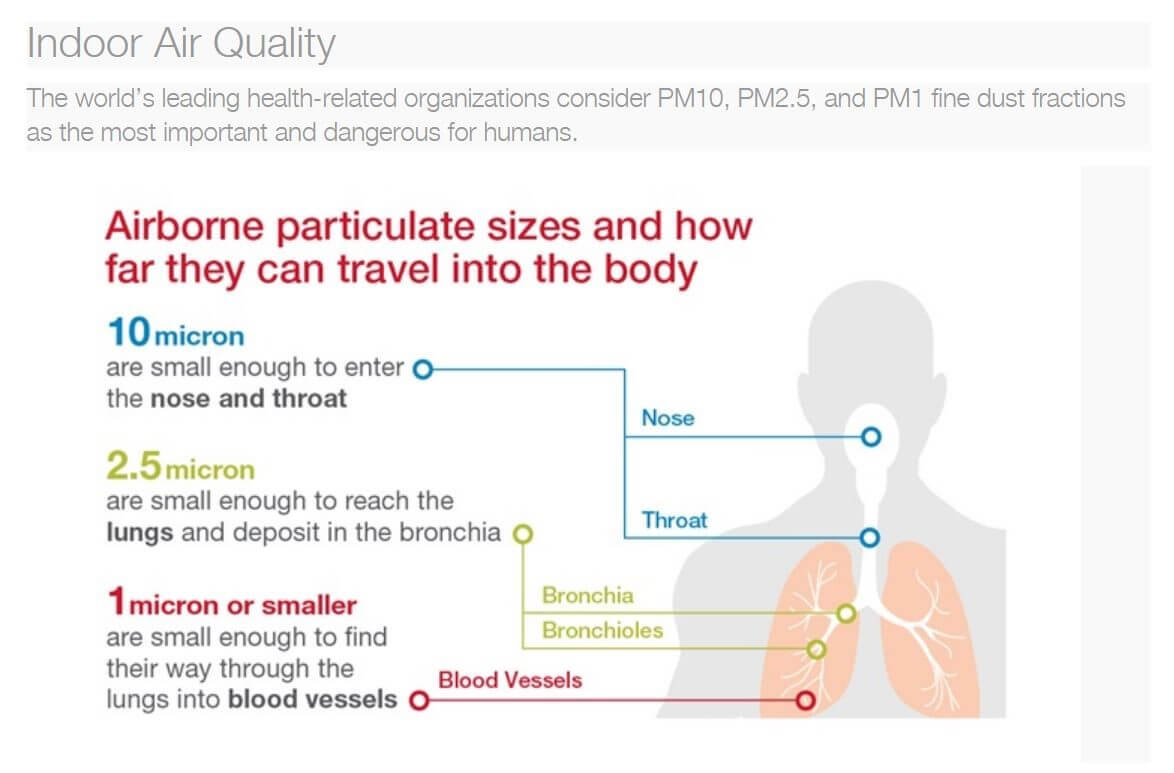

The world’s leading health-related organisations consider Particle Matter or ‘PM’10, PM2.5 and PM1 fine dust fractions to be the most important and dangerous for humans.

‘Heavier dust’ that settles on your table or lap is much larger (typically over 100 microns +) compared to the fine dust in the air around your head and face– It is the fine dust (10 microns and below) that can cause damage and breathing problems.

More often than not, over 50% of the dust you create is INVISIBLE to the naked eye – you simply cannot see it as it is so small. This is the dust that you can inhale deep into your lungs, and that can lead to occupational asthma. (Or ‘respirable inhalable dust’ as can be clearly seen below with a light source).

Fine dusts under 0.5 microns in size, in particular, can be airborne for many hours. ePM1, 2.5 and 10 particle levels can rise exponentially with no form of extraction at all.

Air changes and ventilation are all good and still advisable, but it's like putting a sticky plaster over the problem. What if we could capture these dusts and fumes at source with LEV (Local Exhaust ventilation) - this prevents them from getting airborne in the first place!

The Importance of Extraction at Source

Extraction at source is standard practice in many manufacturing industries.

For example, to remove exposure to solder flux fume and smoke in the electronics industry, we capture the fume before it becomes airborne, and all fine dust and fumes can be filtered 100% with a range of particulate and carbon filters.

This stops it from getting into the operator's breathing zone. Once the filtration system captures the dust (through various forms of capture device), it then filters it through pre/bag filters, then often HEPA filters (99.95% to 0.3 microns or greater) and carbon filters if chemical vapours are present.

This type of extraction system allows clean air to recirculate back into the workshop and avoids any heat loss. Below are some example images of a modular VXJ system, with HEPA and a special Carbon filter unit specifically for Jewellery and Goldsmith processes.

A Call to Action for the Industry

This letter aims to raise awareness among jewellery makers about the workplace dangers and the necessity of investing in proper fume and dust extraction systems.

It is crucial for everyone involved to consider the risks outlined in COSHH regulations and to prioritise the health and safety of artisans.

By advocating for comprehensive extraction solutions, we at VODEX Ltd. hope to prevent harmful substances from becoming airborne, ensuring a safer environment for all.

Paul Riddick

Co-Founder and Technical Director

VODEX Ltd

Author:

Published: