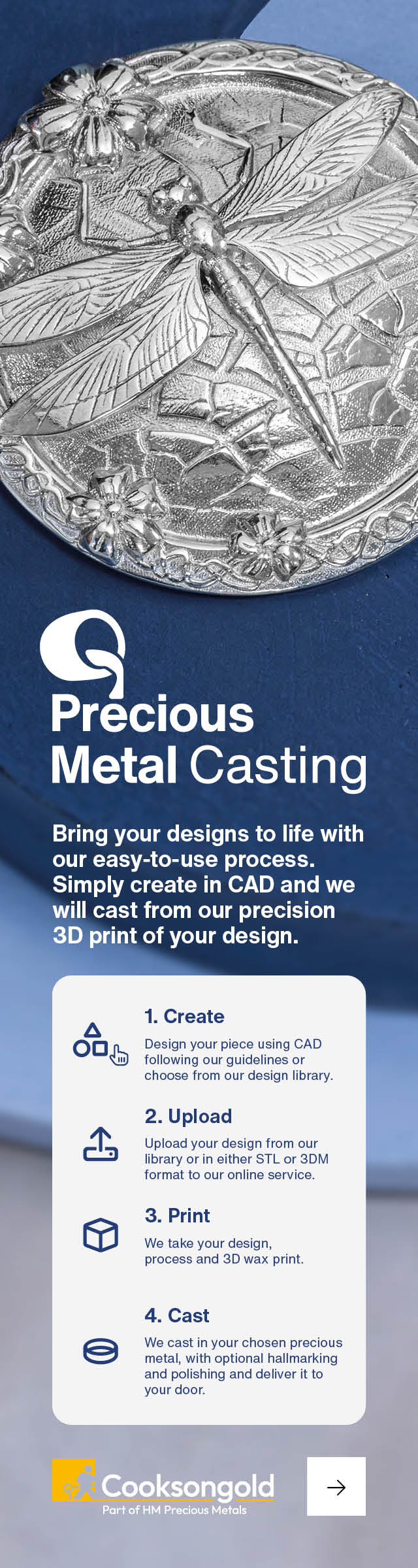

3D printed design Bathsheba

New Technologies make for a growth industry and an emerging one

Reading Time:

1 min {{readingTime}} mins

The advent of electronic mining - the process of extracting gold, silver, copper from discarded electronic objects to make jewellery - is now a growing industry. The 26 year old London based jewellery designer Eliza Walter, Founder of Lylie, is the only jeweller in the UK sourcing all the materials for her designs from ‘urban mining’. Eliza Walter has been awarded a hallmark by the Birmingham Assay Office for her efforts.

Other new technologies in mainstream use include 3D printing in jewellery schools and jewellery manufacturing companies like Weston Beamor (3D printing for jewellery has seen a 450% growth year on year), laser stamping in the Assay Office, to the SYNTHdetect machine, which can separate melee synthetic diamonds from natural diamonds. All of these companies will take part in this year’s fair, including The IIDGR’s showcase of the SYNTHdetect machine and a 3D printing machine.

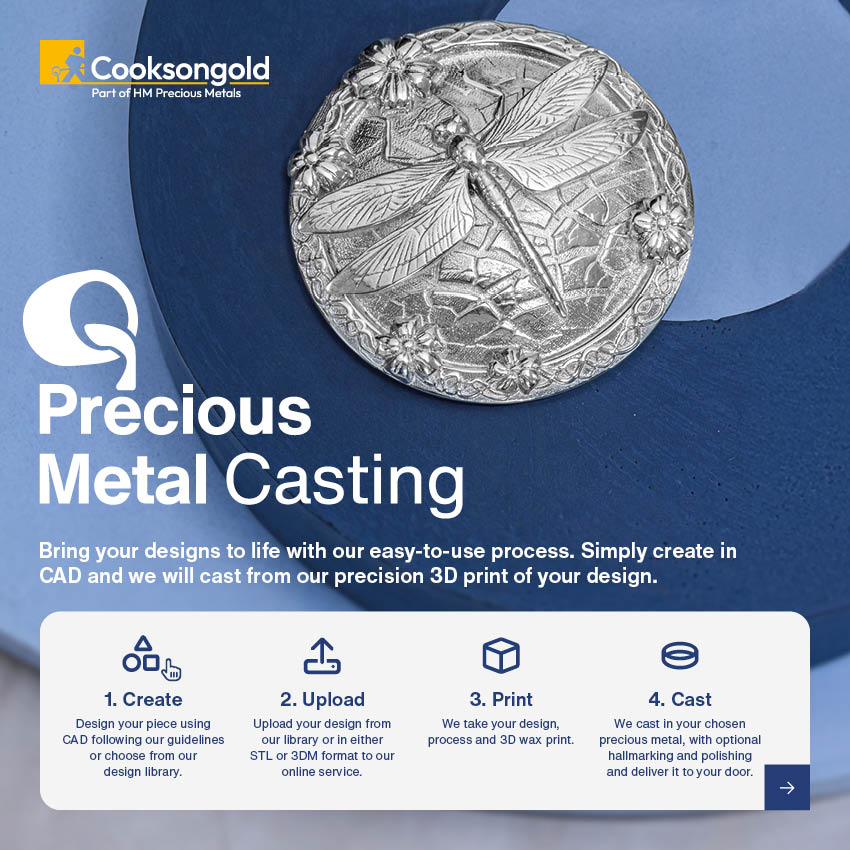

To expand on this Cooksongold and EOS GmBH will be showcasing the first Direct Precious Metal 3D Printing system for Jewellery on the show floor at IJL.

Cooksongold are exhibiting their PRECIOUS M 080 system, the first Direct Precious Metal 3D Printing system designed exclusively for the jewellery, watch and precious metals industries, which is jointly optimised by Cooksongold and EOS GmbH (Electro Optical Systems).

The system expands upon the technology created by EOS to provide jewellery makers with the power and freedom to create complex jewellery in a matter of hours.

The production of innovative jewellery directly from precious metal powders has recently burst onto the manufacturing scene. Known as 3D printing or Additive Manufacturing where powdered precious metal is melted layer by layer using a laser, this technology is being developed by Cooksongold (part of the Heimerle & Meule group) at its facility in the Jewellery Quarter in Birmingham.

Cooksongold 3D, the Bureau Service area of the business, has seen a 450% sales increase year on year as more and more companies

and individuals are starting to design for and adapt to direct precious metal 3D printing.

The technology frees designers from the constraints of conventional manufacturing processes and enables the creation of complex and beautiful parts that are ready to finish in a matter of hours. Parts can be made light-weight, hollow and thus very cost-effective they can also be made with intricate articulation which are highly customisable.

David Fletcher, Additive Manufacturing Business Development Manager, said: “By bringing the system to IJL 2018, we’re hoping to provide an introduction to the technology, displaying how the jewellery industry can now adopt the process as part of their supply chain. We believe that the more people understand about the technology, the more they will be able to push the boundaries of jewellery making by completing previously unachievable designs.”

Author:

Published: